Automatic motor winding machines have changed the assembling scene, offering accuracy, speed, and consistency. At the core of these high level machines lies the job of sensors, which guarantee consistent activity. Understanding how these sensors capability and their advantages can assist producers with arriving at informed conclusions about putting resources into this innovation.

The Basics of Automatic Motor Winding Machines

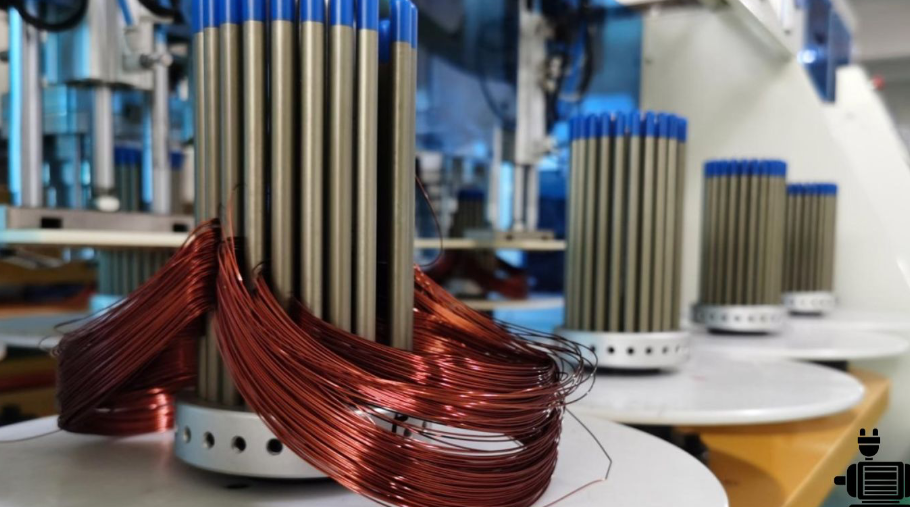

An motor winding machine automatic framework is intended to wind copper or aluminum wires into the motor’s stator or rotor. Dissimilar to manual winding cycles, these machines use trend setting innovations, like sensors, to robotize and advance the activity. This upgrades creation effectiveness as well as fundamentally lessens human blunder.

The motor winding machine cost changes in light of its highlights, intricacy, and the kind of motors it upholds. Nonetheless, sensors assume a critical part in deciding the machine’s presentation and productivity, which straightforwardly influences its offer.

How Sensors Enhance Performance

Sensors are fundamental in automatic motor twisting machines for the accompanying reasons:

Accuracy in Wire Situation

One of the essential assignments of a automatic motor winding machine is to precisely wind the wire. Sensors identify the place of the wire and the winding region, guaranteeing exact position without covers or holes. This degree of exactness limits material waste and upgrades motor execution.

Checking Wire Strain

Keeping up with steady wire strain is basic for the strength of motor windings. Sensors consistently screen the pressure and make continuous changes. This forestalls issues like free winding, which can prompt motor disappointment, or inordinate strain, which might cause wire breakage.

Quality Affirmation

High level sensors recognize anomalies during the winding system, for example, lopsided wire layers or inadequate circles. By hailing these issues early, sensors assist with keeping up with great norms without stopping creation.

Temperature Control

During the winding system, erosion and high velocity tasks can produce heat. Sensors screen the machine’s temperature, guaranteeing it stays inside safe working cutoff points. This forestalls harm to delicate parts and drags out the life expectancy of the machine.

Mechanization and Wellbeing

Sensors empower the mechanization of intricate undertakings, for example, exchanging between wire estimates or changing the winding velocity in view of motor determinations. Also, they guarantee the security of administrators by distinguishing potential risks like wire breakage or part misalignment.

Types of Sensors Used in Motor Winding Machines

A few sorts of sensors are usually tracked down in automatic motor winding machines:

- Position Sensors: Track the wire and twisting region for exact arrangement.

- Pressure Sensors: Measure and manage wire strain.

- Closeness Sensors: Recognize the presence of parts to guarantee legitimate gathering.

- Warm Sensors: Screen the machine’s temperature to forestall overheating.

- Vibration Sensors: Recognize sporadic vibrations, which could show machine wear or harm.

The Impact of Sensors on Efficiency and Cost

The consideration of sensors in an motor winding machine automatic framework can fundamentally affect its productivity. Via computerizing basic capabilities and giving ongoing input, sensors lessen personal time and material wastage.

According to a monetary point of view, while the motor winding machine cost may at first appear to be higher for models furnished with cutting edge sensors, the drawn out benefits legitimize the venture. These machines frequently lead to bring down functional expenses, decreased support needs, and further developed item quality.

Conclusion

Sensors are the unrecognized yet truly great individuals of automatic motor winding machines. They improve accuracy, guarantee quality, and add to the mechanization of basic cycles. For producers, understanding the job of sensors is critical while choosing a machine that adjusts execution and cost.

Putting resources into a sensor-prepared motor winding machine Automatic framework might have a higher forthright expense, however the drawn out reserve funds and proficiency acquires go with it a savvy decision for present day fabricating needs.