The Role of Armature Coil Winding Machines in Precision Coil Manufacturing

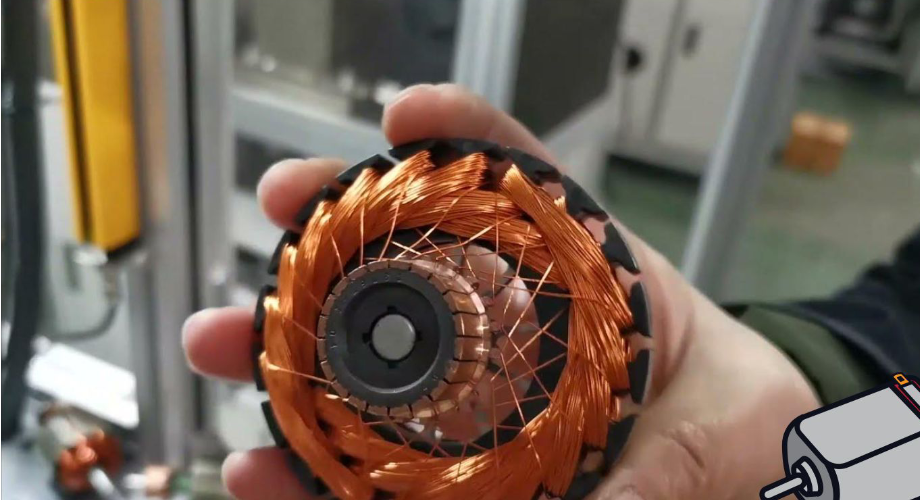

In the domain of electrical designing and assembling, the armature loop winding cycle is fundamental to the creation of elite execution engines, generators, and different other electromechanical gadgets. The nature of the armature coil straightforwardly impacts the productivity, life expectancy, and generally speaking execution of these machines. Armature coil winding machines are refined apparatuses intended to robotize and streamline the loop winding cycle, guaranteeing the most elevated level of accuracy and consistency. This article will investigate the significance of armature twisting machines in accuracy loop producing, their sorts, key highlights, advantages, and contemplations while choosing the right machine for explicit assembling needs.

Types of Armature Winding Machines

Armature winding machine are accessible in a few kinds, each customized to various assembling needs. A few normal sorts include:

Manual Winding Machines:

These machines are worked the hard way and are reasonable for low-volume or custom creation. They give adaptability however require talented administrators to guarantee accuracy.

Semi-Automatic Winding Machines:

These machines consolidate manual activity with computerized highlights. Administrators control a few parts of the twisting system, while the machine mechanizes redundant undertakings like wire taking care of, pivot, and winding pressure.

Fully Automatic Armature Winding Machines:

These machines are the most exceptional, offering rapid and high-accuracy twisting with negligible human intercession. They can consequently change boundaries, like wire pressure, winding rate, and loop count, to meet the ideal determinations. They are great for high-volume creation and applications requiring most extreme accuracy.

CNC Winding Machines:

PC Mathematical Control (CNC) armature winding machines use PC programming to control the twisting system with pinpoint exactness. These machines are profoundly adaptable and can deal with complex winding examples, making them appropriate for accuracy enterprises like aviation or superior execution electric engines.

Key Features of Armature Coil Winding Machines

Automatic Coil Winding Process:

One of the vital elements of an armature loop winding machine is its capacity to robotize the whole winding interaction. This diminishes work costs and takes out human mistakes, guaranteeing high consistency across all coils.

Precision Control:

Accuracy is basic in the armature loop winding cycle. Present day winding machines are outfitted with cutting edge controls that take into account exact acclimations to variables, for example, the quantity of turns, coil shape, and wire pressure. This control empowers makers to meet the specific particulars expected for great armature coils.

High-Speed Operation:

To satisfy the needs of enormous scope creation, numerous armature winding machines are intended for rapid activity without settling on quality. Quicker winding rates add to expanded efficiency and diminished assembling costs.

Wire Feeding Mechanism:

The wire taking care of framework is a fundamental piece of the winding machine. It guarantees that the wire is taken care of without a hitch and uniformly onto the armature center, keeping up with the right strain to stay away from wire breakage and guarantee in any event, winding dispersion.

Tension Control:

Appropriate wire pressure is critical for the presentation and strength of the injury coils. Armature winding machines are outfitted with pressure control components that keep up with consistent strain during the winding system, guaranteeing the wire doesn’t turn out to be excessively close or excessively free.

Coil Formation Control:

Machines are fit for framing loops as indicated by unambiguous examples, for example, lap or wave winding. These different coil structures are basic for accomplishing the ideal electrical attributes and mechanical properties.

Multi-Spindle Capabilities:

Some high level armature loop winding machines include various axles, empowering them to at the same time wind a few coils. This element is great for makers intending to increment yield while lessening creation times.

The Importance of Precision in Coil Manufacturing

Accuracy in armature coil fabricating is basic, as any irregularities in the winding system can prompt issues like expanded obstruction, overheating, and decreased execution of the engine or generator. Off base winding can likewise create issues like unequal loops, which lead to vibrations or lopsided wear. By utilizing an armature loop winding machine, makers can guarantee that each coil is twisted to correct determinations, bringing about a more proficient and solid item.

Benefits of Armature Winding Machines in Precision Coil Manufacturing

Enhanced Efficiency:

Armature winding machines altogether further develop creation proficiency. Via computerizing and accelerating the winding system, makers can fulfill high need while keeping up with steady quality. With quicker arrangement times, machines can create coils at a much faster rate than manual twisting, prompting worked on by and large efficiency.

Higher Precision:

The accuracy capacities of armature winding machines are crucial for creating excellent coils that meet the severe prerequisites of present day electrical frameworks. These machines guarantee the right wire strain, winding example, and loop consistency, taking out the requirement for manual changes and diminishing the gamble of mistakes.

Reduced Labor Costs:

Robotization of the winding system lessens the dependence on talented work, prompting lower work costs. Less specialists are expected to work the machine, which diminishes staffing costs as well as limits human blunder in the creation cycle.

Improved Product Quality:

By giving consistency in each loop wound, armature winding machines add to the creation of top notch electrical parts. This works on the unwavering quality and execution of the finished results, whether they are engines, transformers, or generators.

Understanding Armature Winding Machine Price

The armature winding machine price can differ contingent upon a few variables, including the intricacy of the machine, its creation capacities, and its mechanical elements. By and large, completely computerized machines with CNC combination or various shafts will generally be more costly than manual or self-loader machines. In any case, the cost ought to be viewed as with regards to the machine’s drawn out esteem, including its capacity to increment efficiency, diminish mistakes, and lower functional expenses.

Factors to Consider When Choosing an Armature Winding Machine

While choosing an armature coil winding machine, a few key elements should be thought of:

Creation Prerequisites:

Evaluate whether you really want a machine fit for taking care of high volumes or one reasonable for particular, low-volume runs. Rapid, completely computerized machines are great for huge scope creation, while self-loader or manual machines might be better for more redid work.

Wire Type and Size:

Guarantee the machine is viable with the wire type (copper, aluminum) and size (measure) you intend to utilize. The winding machine ought to have the option to acclimate to various wire breadths and materials.

Spending plan Limitations:

Think about your financial plan and gauge the expense against the machine’s elements, like robotization, speed, and accuracy. A higher beginning speculation might bring about long haul investment funds through superior efficiency and decreased blunder rates.

After-Deals Backing and Upkeep:

Pick a producer that gives solid client care, including preparing, investigating, and admittance to save parts. This guarantees that the machine stays functional and useful long into the future.

Future Development:

Consider the future necessities of your creation interaction. On the off chance that you expect development, putting resources into a further developed and versatile armature winding machine might give more prominent long haul benefits.

Conclusion

Armature coil winding machine are imperative in current accuracy loop fabricating, giving the robotization and accuracy important to make top notch coils for engines, generators, and transformers. These machines offer various benefits, including further developed proficiency, higher item quality, diminished work costs, and limited material wastage. While the underlying expense of an armature winding machine can fluctuate contingent upon its elements, the venture is many times legitimized by the huge upgrades underway speed and quality. By choosing the right machine for their particular requirements, makers can advance their creation processes, diminish expenses, and improve the presentation of their electrical parts.

Post Comment